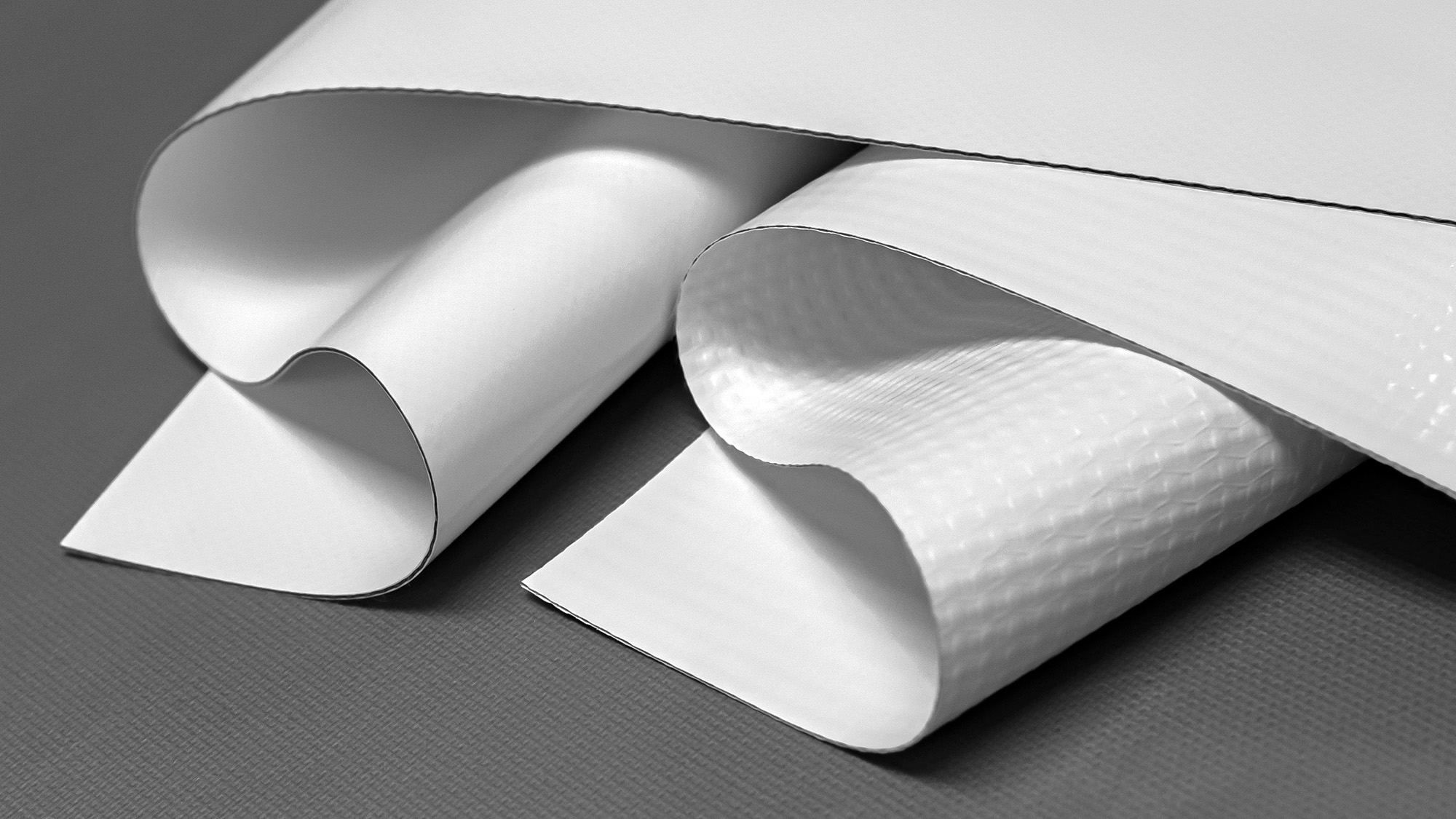

It all comes down to two factors when analyzing what makes an event tent high-quality. First, there are the metal components, such as tent poles and frames, then there are the fabric and vinyl pieces for the tent tops and sides. This raises the question – should a structure utilize PVC laminated or PVC coated fabric? Let’s explore the two options and discover the benefits of using one or the other.

Process Differences

The ounce weight of vinyl is a common measure of its caliber and durability. However, the vinyl’s weight isn’t the only factor to consider when evaluating the quality of a tent top. How the vinyl is applied to the base fabric, whether that be laminating, or coating has a major impact on performance and function.

Laminate materials are held together by fusing the top and bottom layers into place through the open areas of the base fabric, thereby adhering to each other. Small-size tents, coverings, banners, and tarpaulins can be constructed using laminates because they are lightweight, durable, and a great cost for quality.

PVC coating, on the other hand, is bound to the base cloth using a unique adhesive method. The initial step in this method is to apply a strong glue to each foundation fabric thread. The liquid PVC coating is then applied to the adhesive and fused together using heat and pressure. As a result of this bonding process, PVC coated fabrics have stronger abrasion resistance than laminated fabrics – but are also more expensive to produce. For large structures, architectural, high-end events, and weatherproof coverings, PVC-coated fabric is crucial.

Considerations

Each fabric has advantages and disadvantages and should be weighed depending on the size, style, environment, intended strength, and purpose of a project. Small, short-term projects that rely on a cost-effective solution are better suited for laminated fabrics, whereas robust structures that demand higher performance and longer wearability will require coated options. Despite this, PVC laminated vinyl has great weight-to-strength ratios and should not be overlooked.

Pros of PVC Laminated Fabrics:

- Cost-effective

- Wider range of colors

- Great strength-to-weight ratio

Cons of PVC Laminated Fabric:

- More difficult to clean

- Less resistant

- Lower longevity

Pros of PVC Coated Fabric:

- Smoother finish

- Higher Strength and Durability

- Increased longevity

- Better suited for wind and cold weather

Cons of PVC Coated Fabric:

- Higher Cost