What is Keder

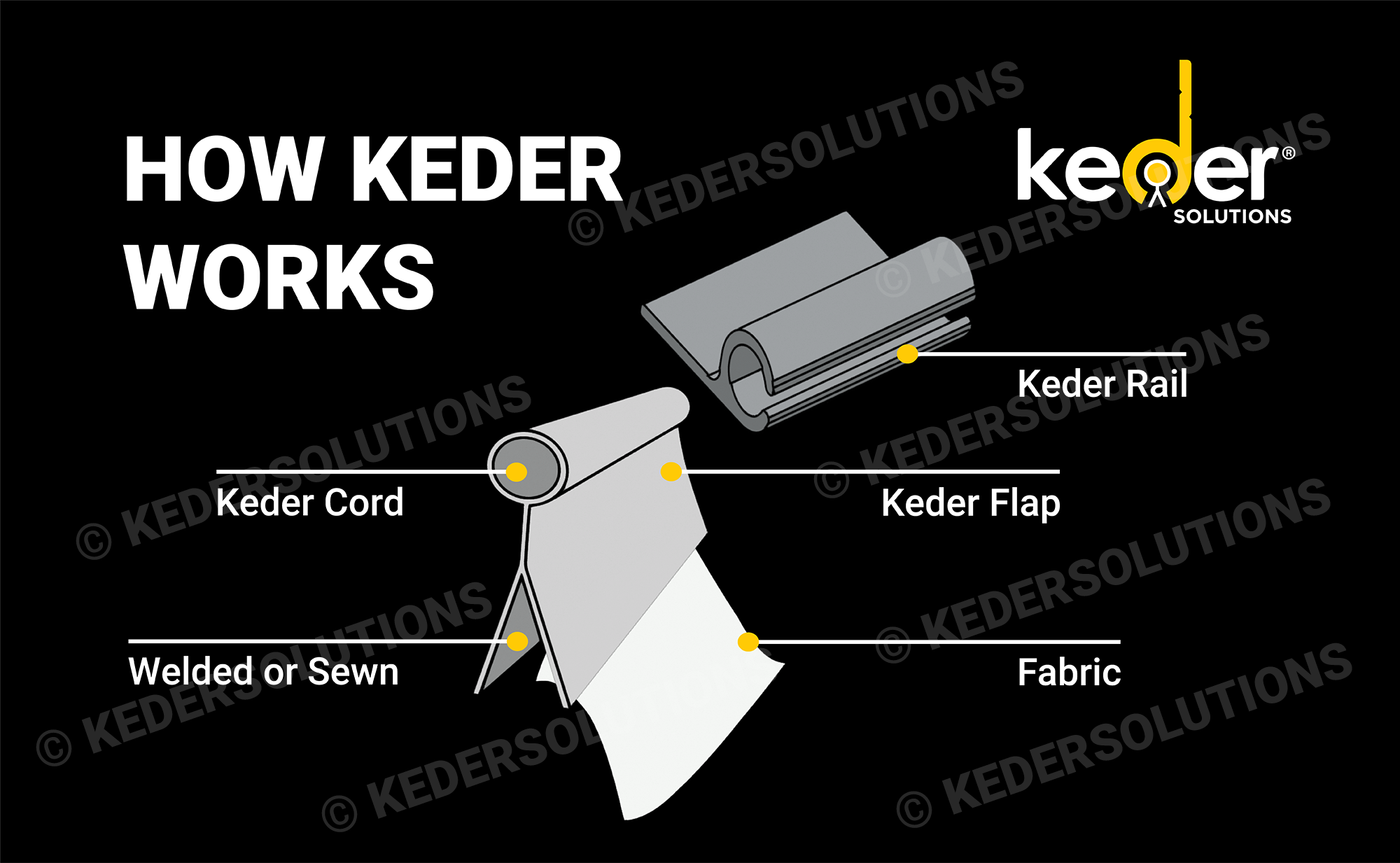

Keder consists of two parts: a core and fabric. The core is made from extruded PVC, or another elastic material, to allow flexibility. The core is then wrapped in Keder fabric, which has exposed fibers on the outside to allow the Keder to easily slide into an extrusion with a luff groove – keder track. It has coating on the inside, to ensure proper adhesion during welding. For maximum strength, there is a Double Coated Keder available.

- Banner & Fabric Signage

- Dock & Door Seals

- Industrial Curtains

- Marine Products

- Pool Covers

- Tarpaulins (Tarp)

- Tension Textiles & Fabrics

- Tents & Fabric Structures

- Shade & Canopies

What is keder used for?

Keder is attached to fabric to create a continuous water proof connection between fabric and frame. Keder is used in a variety of applications including both permanent & semi-permanent tents & structures, banners, building wraps, facades, awnings, curtains and marine products.

Is “keder” referred to by other names?

Indeed, “keder” is not the only word for this product, other common names include “kador”, “ketter”, “kedder”, “keter”, “boat rope”, “sail rope”, “edge reinforcement”, “hem rope”, and “welting”. We use the term “keder” because it is the most commonly used, and most recognized in the industry.

Which method is best to connect keder to fabric, sewn or welded?

The method for welding keder to fabric depends on the style that is being used. Double flap keder is generally welded using a radio-frequency welder due the fact that, three layers of fabric are welded at the same time. However, Single flap keder can be welded using wedge welders or hot air welders, requiring only a simple overlap weld. Keder can also be sewn to fabric, like the Welded keder flap.

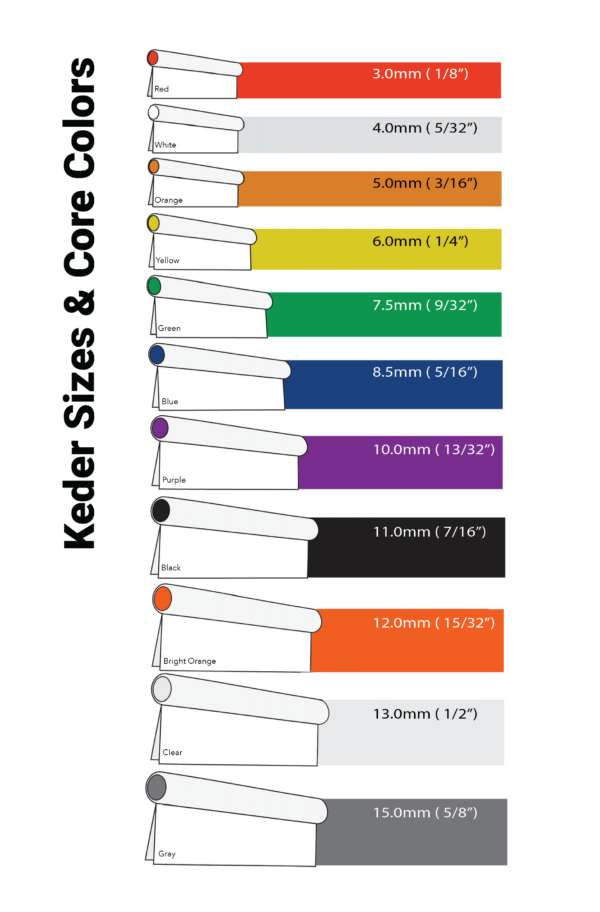

Which size of keder is best for the project?

If you are using Repair keder on a current project, measure the diameter of the current PVC cord. For new keder projects, look at the rail/frame system that the keder will be sliding into. Make sure to order keder that is just a slightly smaller than the diameter of the channel. We would be happy to assist you with your selection, contact our friendly sales staff with any questions!

Which style of keder is best to use? Single, Double, Repair or Welded Flap?

There is really no “correct” answer for this, it is a personal choice based on your project. However, we recommend using specific styles for certain applications.

Single Flap Keder – Awning, banner & canopy industries, unless the keder will be continuously exposed to outdoor elements, then we recommend Double Flap Keder for extra protection.

Double Flap Keder – Tenting & structure, industrial curtain, pool cover, tarpaulin and trampoline industries.

Welded Flap Keder – Marine industry. The welded flap keder MUST to be sewn onto fabric. The majority of marine companies use welded flap keder rather than welding themselves.

Which keder size fits which keder rail?

Most keder rails work with multiple sizes of keder. It’s a good idea to choose a size smaller than the rail because we do have a tolerance on our keder. For example: our 13mm rail has a diameter of 14mm, we would suggest using a 13mm or 11mm keder.

What is the difference between Laminate and PVC Coated fabrics?

PVC Coated Fabric is a more heavy-duty fabric that is usually used on the tops of a tent/structure and Marine Applications. Laminate Fabric is used for many applications such as: soft signage, banners, smaller tents or sidewalls, tarps & covers. Both vinyl types have translucent and blockout options.

Want to learn more about the difference in Coated vs Laminated Vinyl Fabrics, click here to discover what you need to know in our Blog post.